Before you buy a Casted Brake Shoe, make sure to check the quality of the product. If you find it to be cheaply made, it might lead to problems with your brake. In addition, a poor quality shoe might not fit in your brake drum properly, which may cause additional problems. When you buy a Casted Brake Shoe, it should fit snugly into the brake lining, without sliding around in the drum.

To determine the carbon content of a cast iron brake shoe, the total carbon equivalent is determined. It is made up of the carbon content of the casting material, and the carbon equivalent of each additional element. These values are usually measured by experiment. A recent study was conducted to find correlations between the hardness of brake shoes made of cast iron, and the chemical composition of the component parts. In the case of cast iron brake shoes, a basic alloying element was chosen as a representative alloying element. The results of this study revealed that very small differences exist in the hardness of brake shoes, despite the fact that they were within the range of international standards.

The Casted Brake Shoe has many advantages over its tubular counterparts, including light weight, ease of assembling, and flexibility. A Casted Brake Shoe is also typically made of a malleable iron material, which is stronger and lighter than the standard version. In addition to being lightweight, it also resists corrosion. It is also easier to manufacture than a traditional brake shoe. The advantages of the Casted Brake Shoe make it a popular choice for a variety of vehicles.

Cast steel is the most common material for brake shoes. While it can be a good choice for heavier duty applications, ductile iron is better for lighter-duty use. Due to its high phosphorus content, aluminum alloys make excellent brake shoes. While neither material is perfect for the other, the balance of the compounds in a cast brake shoe is ideal. Ultimately, the Casted Brake Shoe will last longer with proper care and attention.

A third type of brake shoe is made of steel. A cast brake shoe is a great choice for high-performance cars because of its weight, durability, and low price. Casted brake shoes are much lighter than steel, but are still stronger than standard brake shoes. The difference in weight can cause a noticeable impact on brake noise. If you're not satisfied with the quality of your brake shoes, you should consider replacing them.

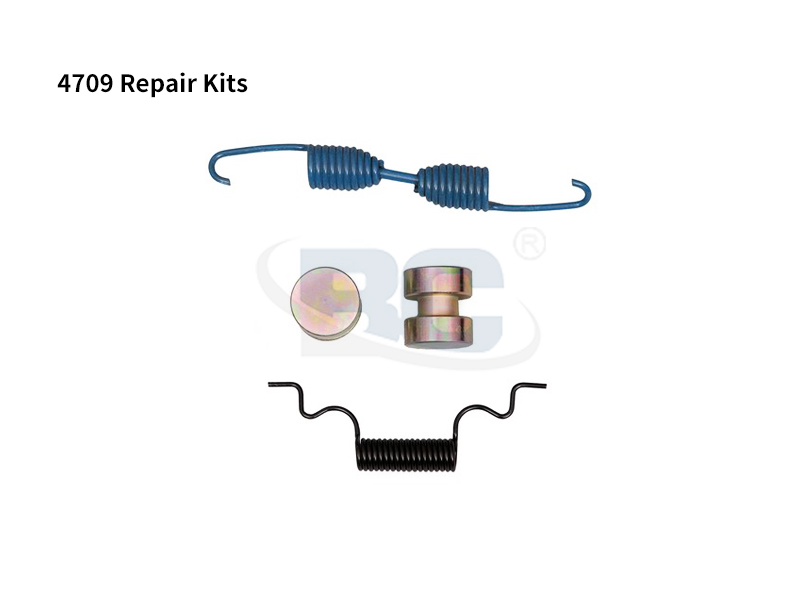

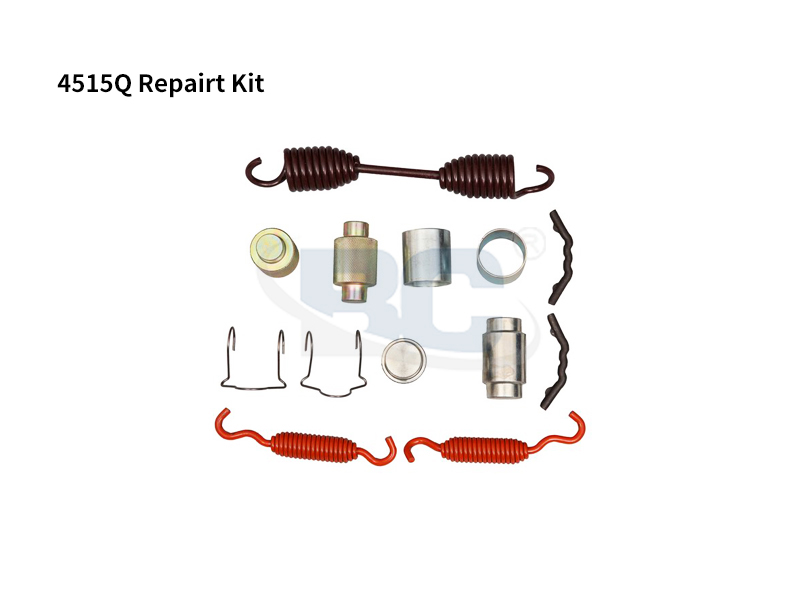

Another type of brake shoe assembly has been proposed, and is made of a steel plate with a plurality of raised tabs or perforations. These raise tabs create interlocking engagement. This friction material is molded to fit each other and be seated in the perforated areas. A pressed steel core is another option. This material can be hardened or softened to suit your vehicle. A spring is also included to bias the brake shoes out of braking engagement.

English

English 简体中文

简体中文