Brake lining bearings are the lubricant-filled surfaces in brake systems of all types, including drum brakes and disc brakes. When properly used and maintained, these components to prevent damage to the brake pads by creating a lubricant film that locks the components together. This film also helps to keep the brake pads from drying out, which causes premature brake failure. However, when this film is not properly cared for, it can lose its adhesive properties and start to peel off, causing brake failure. Proper maintenance and care of brake lining bearings will extend the life of your brakes by keeping them working smoothly.

Brake pads can lose their adhesives because of several reasons, such as heat damage, oxidation, and rust. The surface area of the pad may become distorted over time, which can make it ineffective and even cause the seal to break. The improper cleaning and maintenance techniques, such as cleaning and painting the rotors too frequently, can also lead to rotors wearing thin, exposing the sticky resin that lies beneath. Rotors with thin layers of this resin will lose their adhesive strength and fail much sooner.

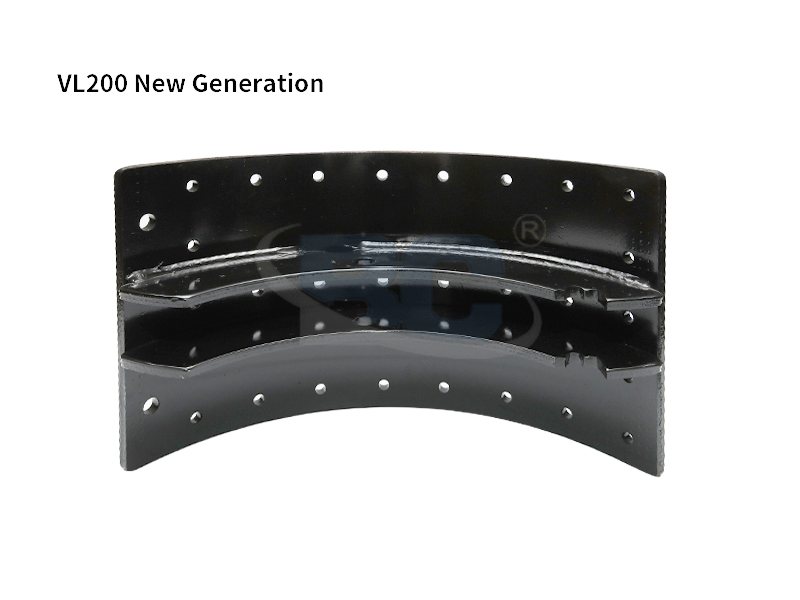

Brake lining materials include friction material and a rubber compound. The friction material acts as a lubricant, allowing the brake components to work properly. The rubber compound adds tensile strength and makes the friction material more resilient against abrasion and other damage. The compound also protects the rubber component from wear and provides a friction layer that retains the heat and abrasions of the brakes, preventing damage to brake rotors.

Brake pads and drums also need to be regularly inspected to check for signs of deterioration. Brake pads can start to degrade as soon as they are abused or overworked. The constant rubbing caused by the pads themselves causes a thin film to form on the underside of the rotors. This allows the friction material to become more brittle and eventually break off completely from the brake caliper. Over time, if the braking system is abused, brake pads can build up a thick layer of this material, which decreases the amount of braking force that is transmitted through the pads themselves. This means that in addition to the performance of the brakes being reduced, one may also experience a loss of braking power and even brake failure.

A thin layer of the friction material is also built up on the brake disc. The disc is made of rubber and its core is surrounded by a highly stiff liner. When pressure is applied to the disc at any point, the rubber liner conforms to the shape of the pressure, which results in a stronger brake pad than one could produce without using the special brake lining. The lining is specially designed so that it can withstand the force that is exerted on the disc, preventing the rim and brake line from breaking when the pressure is applied to the pad.

Rotors also need to be regularly serviced to make sure that they are working correctly and have proper contact with the brake pads. A buildup of brake dust, mineral deposits, and brake fluid means that if the rotors are not properly serviced, the performance of the braking system will be negatively affected. When the rotors stop, the brakes lose their braking power and stop quickly. This can reduce safety, cause accidents, and affect the resale value of your vehicle should you ever decide to sell it.

English

English 简体中文

简体中文