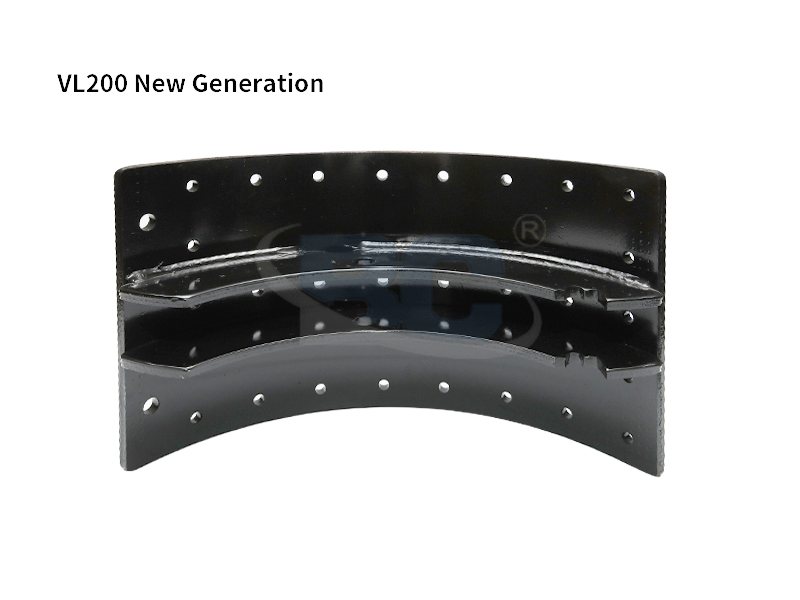

A Casted Brake Shoe is a type of automotive brake shoe. The process involves pouring hot metal into a mold assembly. This molten metal is usually malleable or ductile iron. It flows through gates 55 and 56, and into the mold cavity for the brake-shoe. The molten metal is then straightened and coined to fit the shape of the shoe. It can be made from any suitable metal, but ductile iron is preferred.

The casting process produces a cast-iron brake shoe with a curved edge. This chamfer allows the brake lining to be mounted directly onto the casting surface. The process reduces the need for machining the outer table section, thereby reducing both the production time and the cost of the finished product. For more information, visit the Casted Brake Shoe page. What is a Casted Car Break Shoe?

The Casted Brake Shoe is a type of car brake. It's an integral part of a vehicle's braking system. The brake shoe is secured to the vehicle's rim with a perforated metal backing plate. The surface is then cast to its final size and dimension. The shoe is then machined to fit the rim. A Casted Brake Shoes may be used in both new and reconditioned automobiles.

In some cases, a Casted Brake Shoe is not necessary. It's possible to cast the brake shoe table section without a parting line. Once the outer table section is cast, the brake lining can be installed directly onto it, eliminating the need for machining. In addition to reducing production time, a Casted Brake Shoe saves money. It's also an environmentally friendly option.

The present invention provides a new method of casting a Casted Brake Shoe. Its main feature is a cast brake shoe table section that includes a curved table section and at least one rib section. The outer curved surface of the table is then machined to the final size and dimension, which allows for an exceptionally smooth and durable brake shoe. Its unique design allows for the mounting of the brake lining directly on the outer surface.

The Casted Brake Shoe is a new type of brake shoe. It features a cast brake shoe table section and a layer of friction material. The brake shoe is attached to the brake lining 17 by threaded fastener 14. The backing plate 16 has a plurality of threaded bosses 18 and 22. This is a common design for the brake shoe. Its raised tabs are an important feature of the Casted Broke Shoes.

The present invention provides a method of making a Casted Brake Shoe. The brake shoe is formed using a curved table section and at least one rib section. The table section is cast in a mold with a cope and drag sections. The curved surface of the table section is substantially parallel to the parting plane of the mold sections. The brake shoe is then heat-treated. The present invention is a method of casting a Casted Tire

English

English 简体中文

简体中文